1-6kW 3D 5-axis laser cutting machine TF4025

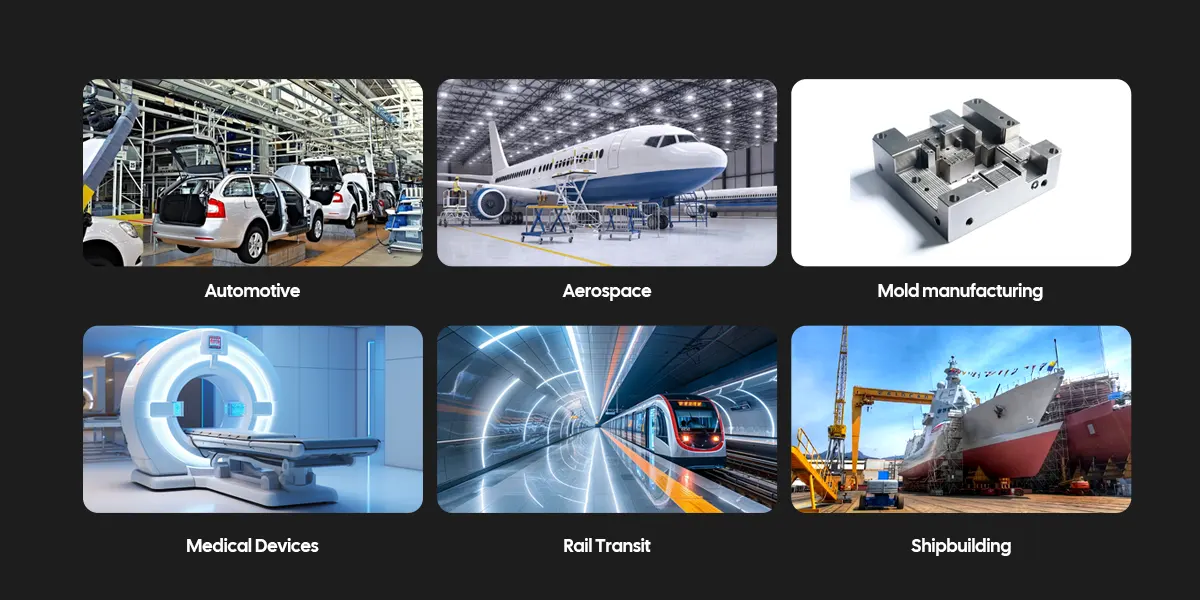

3D 5-axis laser cutting machine with excellent design and advanced technology, in the aerospace, automotive manufacturing, precision mold and other high-end manufacturing industry shine, can accurately and efficiently process complex parts.

- Laser Power: 1kW-6kW

- Processing Area: 4000*2500mm

- Maximum Axis Rotation Speed: 120r/min

Performance Advantages

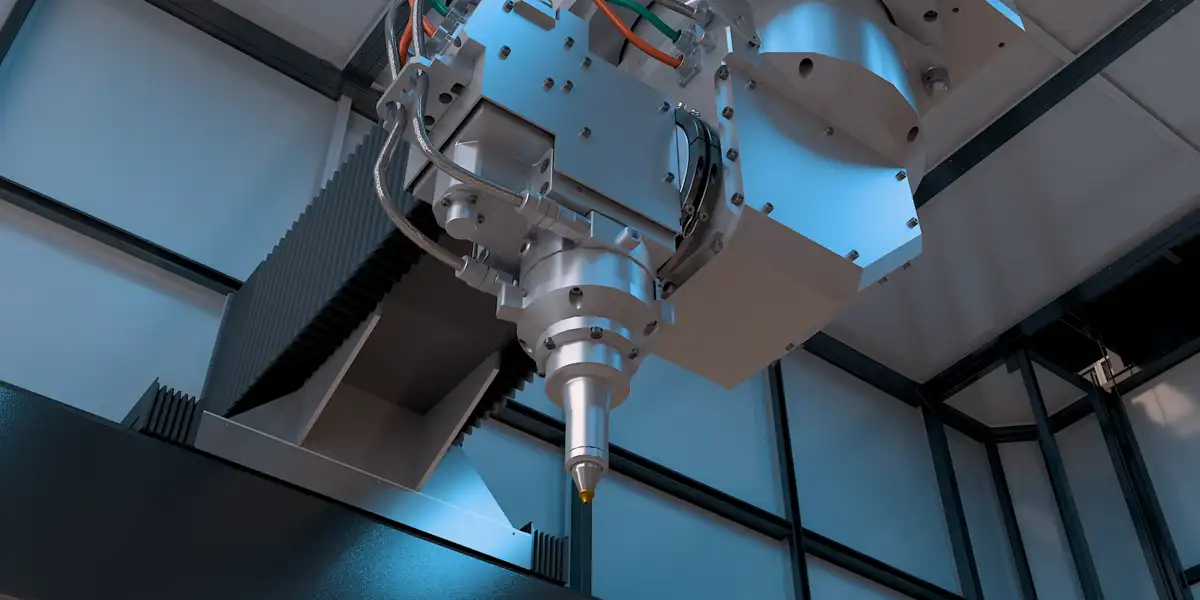

The machine’s cutting axis angle switching is fast, and it can respond to all kinds of cutting paths at any time, realizing 24-hour uninterrupted and stable production, and greatly improving the processing efficiency, which is the ideal choice for three-dimensional shaped surface cutting.

Excellent appearance and function

- The whole machine has an encircling design and sturdy structure, which prevents sparks from flying and isolates the laser radiation and reduces the spread of fumes. The independent monitor display provides real-time information on the work status.

Omni-directional cutting

- The machine can realize three-dimensional cutting and flat plate cutting of carbon steel, stainless steel, aluminum alloy, titanium alloy, copper and other metal materials. It is also compatible with complex workpieces such as shaped pipes, stamping parts, casting parts, etc., solving the problems that cannot be processed by traditional techniques.

| Model | XT-TF4025 |

| Laser Power | 1kW-6kW |

| Processing Area | 4000*2500mm |

| Y-axis Travel/Max. Speed | 2500mm / 90m/min |

| X-axis Travel/Max. Speed | 4000mm / 90m/min |

| Z-axis Travel/Max. Speed | 800mm / 50m/min |

| C-axis Travel | ±360° |

| A-axis Travel | ±135° |

| W-axis Travel/Max. Speed | ±12.5mm / 30m/min |

| XYZ Positioning Accuracy | ±0.03mm |

| XYZ Re-positioning Accuracy | ±0.02mm |

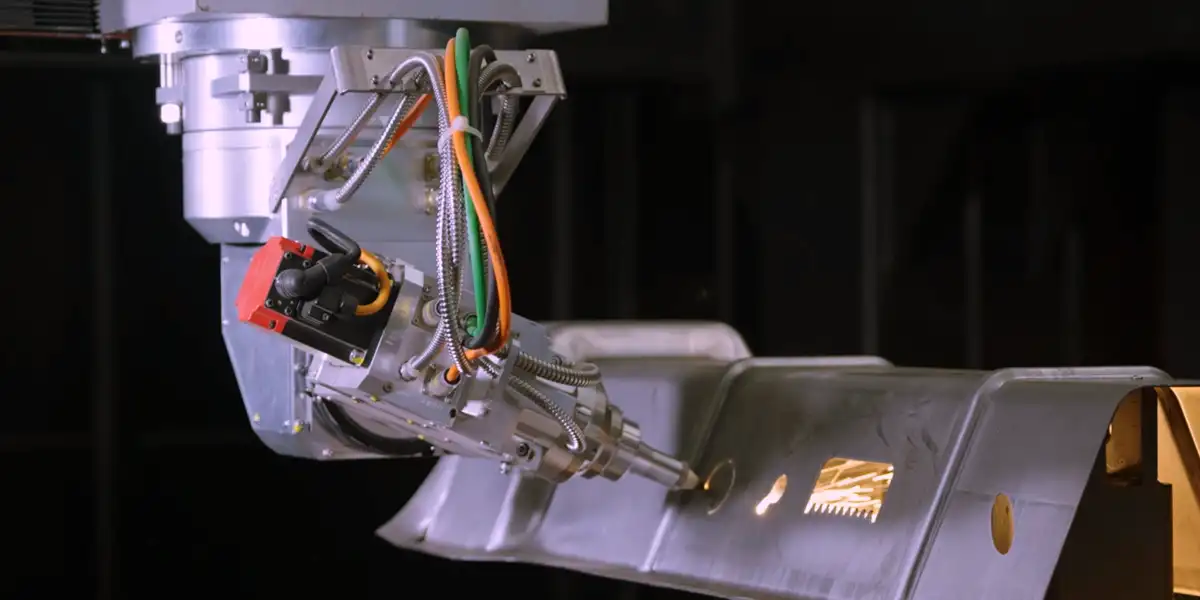

Mechanical Advantages

The machine is equipped with a high-precision 5-axis linkage cutting head, which can realize 360°rotation and ±135°swing, and the cutting path is fast and accurate, so it can easily cut complex curved surfaces.

Easy cutting of complex surfaces

Cutting table (optional)

Efficient rotation of two stations (optional)

What you'll love about 3D 5 axis laser cutter

3D 5-axis laser cutter allows for more complex cutting shapes such as geometric, curved and flat cuts.

TF4025 laser cutting machine is equipped with 5-axis linkage cutting head, supporting both flat and 3D cutting.

High-precision control, real-time synchronized feedback, signal stability and anti-interference, efficient integration of intelligent processing.

The cutting head adopts anti-collision induction design, which can avoid the laser head damage caused by the collision between the cutting head and the plate.

5 aixs 3D laser cutting machine can be used in automotive manufacturing, aerospace, mold manufacturing, medical equipment, rail transportation and other industries.

Worry-free service guarantee

We value the real needs and user experience of our customers and provide timely and effective services to global customers.

Warning: imagepng(/www/wwwroot/www.xtlaser.net/wp-content/uploads/elementor/thumbs/2025052082-r6ix45x5p2y12irqx75i46ssicfc9nbjzpy5b8z9q8.png): failed to open stream: Permission denied in /www/wwwroot/www.xtlaser.net/wp-includes/class-wp-image-editor.php on line 585

Machine maintenance

During the warranty period, maintenance personnel will provide on-site maintenance services, covering mechanical structure, electrical system, control system, etc.

Warning: imagepng(/www/wwwroot/www.xtlaser.net/wp-content/uploads/elementor/thumbs/2025052046-r6ix45x5p2y12irqx75i46ssicfc9nbjzpy5b8z9q8.png): failed to open stream: Permission denied in /www/wwwroot/www.xtlaser.net/wp-includes/class-wp-image-editor.php on line 585

Flexible training

XT LASER provides online/offline free combination training programs, you can freely choose according to your needs.

Warning: imagepng(/www/wwwroot/www.xtlaser.net/wp-content/uploads/elementor/thumbs/2025052018-r6ix45x5p2y12irqx75i46ssicfc9nbjzpy5b8z9q8.png): failed to open stream: Permission denied in /www/wwwroot/www.xtlaser.net/wp-includes/class-wp-image-editor.php on line 585

Global spare parts supply

Adopting the "proximity principle" to provide original accessories for global users, and the headquarters central warehouse will ship within 3-5 working days.

Warning: imagepng(/www/wwwroot/www.xtlaser.net/wp-content/uploads/elementor/thumbs/2025052097-r6ix45x5p2y12irqx75i46ssicfc9nbjzpy5b8z9q8.png): failed to open stream: Permission denied in /www/wwwroot/www.xtlaser.net/wp-includes/class-wp-image-editor.php on line 585

All-day technical support

7×24 hours three-level response (emergency problems within 30 minutes), remote guidance + real-time update of process parameter library.

FAQs

Have any questions? The following FAQs can solve your confusion.

What materials can fiber laser cutting machines cut?

Fiber laser cutting machines can cut most metal materials, including stainless steel, carbon steel, aluminum, copper, alloy steel, galvanized sheet, titanium, etc. They are widely used in sheet metal processing, kitchen utensils, aerospace, metal cabinets, automotive parts, construction and other industries.

What are the advantages of laser cutting machines over other cutting methods?

Laser cutting technology has significant comprehensive advantages over traditional cutting methods (such as flame cutting, plasma cutting, waterjet cutting).

- High precision laser cutting, narrow kerf width, smooth and burr-free, small heat-affected zone, no need for secondary grinding and polishing.

- Non-contact processing, no mechanical stress, avoiding tool wear or material deformation.

- Optimize cutting path through intelligent nesting system, reduce edge waste and save processing cost.

- Support seamless connection with intelligent control system (e.g. bus communication, automatic loading and unloading, visual positioning) to realize 24-hour unmanned production.

- Fiber laser electro-optical conversion rate>30%, low energy consumption, cost-effective.

- Can quickly switch the cutting pattern, high cutting efficiency, saving time and cost.

Does XT LASER equipment comply with international safety standards?

Our equipment is CE certified, equipped with a fully enclosed protective chamber, emergency stop button, laser protection interlocking system, and complies with ISO safety norms, so you can purchase and use it with confidence.

What is the laser power and accuracy of this machine?

The laser power of XT LASER 5 axis 3D laser cutting machine can be selected from 1000-6000W, the positioning accuracy is ±0.05mm, and the repetition accuracy is ±0.03mm, which is suitable for high-precision cutting of complex curved surfaces.

Is routine maintenance complicated? What is the life span of consumables?

- The laser and cutting head adopt modular design, only the guide rail and lens need to be cleaned in daily life. The life of the focusing lens is about 6-8 months and the nozzle life depends on the frequency of use, usually 2-4 weeks.

How difficult is it to operate a laser cutting machine? Does it require professional training?

XT LASER’s sheet metal laser cutting machine is equipped with a visual operation interface and a detailed operation manual, so even if you are a novice, you can quickly get started. If you are a beginner, it is recommended to read the safety guide before use, or contact our professional technicians online.

Contact Us

Contact us for professional technical support, online quotes, catalogs or demo videos.