1.5-12kW high-performance laser cutting machine W1530 2.0

The machine supports cutting 1-25mm stainless steel/carbon steel, and the cutting width can be customized according to requirements. Equipped with special cutting system, it is easy to operate, high precision and professional, supporting whole board and multiple boards to be loaded and cut at one time, which greatly improves the cutting efficiency. A 40HQ high cabinet can accommodate 8 sets of equipment, reducing logistics costs.

- Laser Power: 1.5-12kW

- Processing Area: 1530*3050 mm

- Linkage Speed: 120 m/min

Performance Advantages

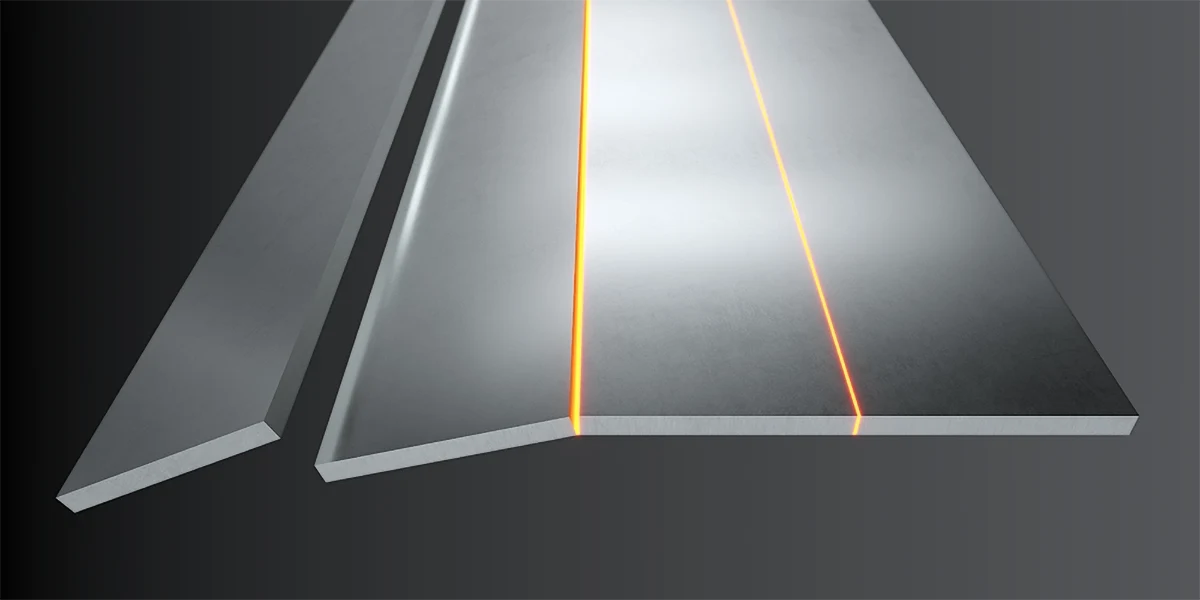

The machine is available with 1.5kW-12kW power and is specially developed for cutting medium-thick metal plates. Stable performance, high precision and smooth cutting edges can greatly shorten the production cycle.

Integrated design

- Adopting advanced automation and integration technology, it is stable and reliable, with reasonable internal structure arrangement, small footprint, and flexible placement. 40HQ high cabinet can contain 8 machines.

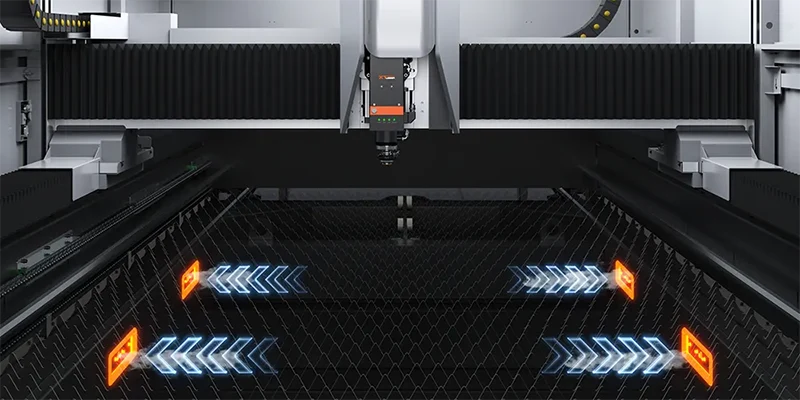

Intelligent Fault Alarm

- XT LASER self-developed warning light, sound and light synchronization prompts, real-time feedback equipment status, there are problems can be found in time.

Near-point dust extraction system

- There is a dust extraction function at the near point of the bed, which can efficiently filter and accurately extract the smoke and dust in the process of machining. This improves the working environment and protects the health of operators.

| Örnek | XT-W1530 2.0 |

| Çalışma alanı | 1530*3050mm |

| Linkage Speed | 120 m/dak |

| Max. Load | 800kG |

| Konumsal Doğruluk | ±0,03 mm |

| Repositional Accuracy | ±0,03 mm |

Mechanical Advantages

The equipment has excellent structural design, solid bed, safe and reliable.

Z-axis sealing module

Quick-release cable routing

Rolling support loading

Control System Advantages

The equipment is equipped with a professional control system and built-in multiple functions, which can greatly improve processing accuracy and efficiency, reduce failure rate and save costs.

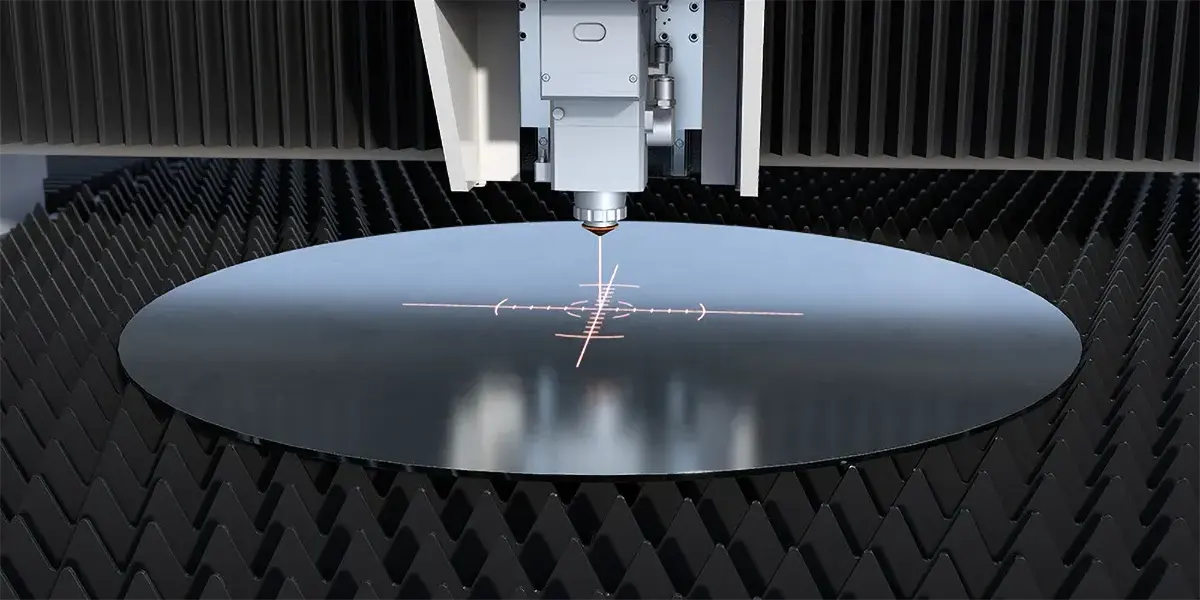

After scanning the edges of the sheet through the laser sensor, the system algorithm locates the geometric center of the sheet or workpiece, ensuring that the cutting path and material position are precisely matched, thus improving cutting accuracy and material utilization.

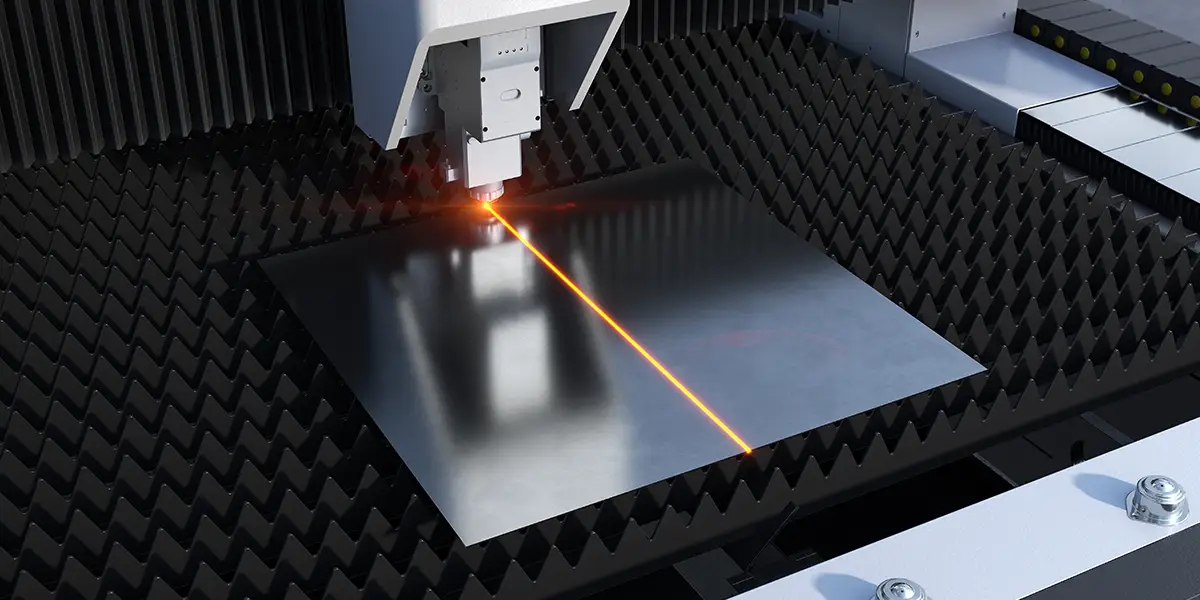

Quickly cut off the sheet, cut off the edge, and recover the whole remaining tail material, convenient for reuse.

The surface of the metal workpiece after laser cutting is clean and remains partially connected to the remaining material, which prevents the workpiece from shifting and helps to achieve batch unloading and high-efficiency production.

Real-time monitoring of the distance between the cutting head and the workpiece or table, and automatically adjusts the height or stops the machine before a possible collision to protect the cutting head and the workpiece from damage.

Worry-free service guarantee

We value the real needs and user experience of our customers and provide timely and effective services to global customers.

Machine maintenance

During the warranty period, maintenance personnel will provide on-site maintenance services, covering mechanical structure, electrical system, control system, etc.

Flexible training

XT LASER provides online/offline free combination training programs, you can freely choose according to your needs.

Global spare parts supply

Adopting the "proximity principle" to provide original accessories for global users, and the headquarters central warehouse will ship within 3-5 working days.

All-day technical support

7×24 hours three-level response (emergency problems within 30 minutes), remote guidance + real-time update of process parameter library.

FAQs

Have any questions? The following FAQs can solve your confusion.

What materials can fiber laser cutting machines cut?

Fiber laser cutting machines can cut most metal materials, including stainless steel, carbon steel, aluminum, copper, alloy steel, galvanized sheet, titanium, etc. They are widely used in sheet metal processing, kitchen utensils, aerospace, metal cabinets, automotive parts, construction and other industries.

What software does the laser cutting machine need to support? What file formats are compatible?

Fiber laser cutting machines require professional laser cutting control software and CAM software to process design files and generate cutting paths, such as LightBurn, AutoCA, etc., and are compatible with DXF, SVG, AI (Adobe Illustrator), EPS, DWG, PDF, PLT, etc.

What is the maximum processing size of the W series 2.0 laser cutting machine?

The maximum processing size of the workpiece currently supported by the W series 2.0 is 1530*3050 mm and 2540*6100 mm, as long as your plate size is within this range.

How to choose laser power?

The laser power of the laser cutter depends on the cutting material and thickness. If you don’t know how to choose the right power for your device, please contact us.

How difficult is it to operate a laser cutting machine? Does it require professional training?

XT LASER’s sheet metal laser cutting machine is equipped with a visual operation interface and a detailed operation manual, so even if you are a novice, you can quickly get started. If you are a beginner, it is recommended to read the safety guide before use, or contact our professional technicians online.

Does the machine require special ventilation or cooling systems when working?

Yes! Laser cutting of metal materials will produce smoke and dust. Under the premise of ensuring ventilation, optional dust collection equipment can be used to reduce environmental pollution.

In addition, the machine’s built-in water cooling/air cooling system ensures the stability of the equipment for long-term operation.

Bize Ulaşın

Profesyonel teknik destek, online teklifler, kataloglar veya demo videoları için bizimle iletişime geçin.